veneers

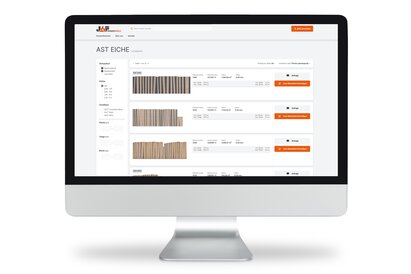

Revolution in veneer sales

Veneers are unique products. Sheet for sheet, every cut leads to a stand-alone product. To open this world of diversity to its customers, JAF has created its veneer-world.com website as the world’s first-ever online veneer shop with high-resolution images. Customers can inspect 12 million square metres of veneers made from more than 180 wood species and around 1.2 million high-resolution images of veneer surfaces in this online shop. This makes it possible to identify and evaluate the exact structure of every single bundle.

Fleece-backed solutions

Processing veneers requires a high degree of craftsmanship. To make processing easier, JAF also includes fleece-backed veneers in its product range. The fleece backing adds stability to the veneer. This makes it easier to process and possible to veneer multidimensional projects and difficult surfaces.

Bespoke services

Premium veneers highlight the particular character of the wood and add a unique flair to objects or even whole rooms. Joining veneer sheets also requires an exceptionally high level of craftsmanship. Whether for furniture production, individual applications such as in the automotive industry, for the manufacture of musical instruments or industrial processing – JAF offers its customers joined veneer sheets based on their specific requirements.

product overview

- Sliced veneers

- Butt cut veneers

- Fleece-backed veneer sheets